How the SH-FL03 Saves 30% on Falafel Frying

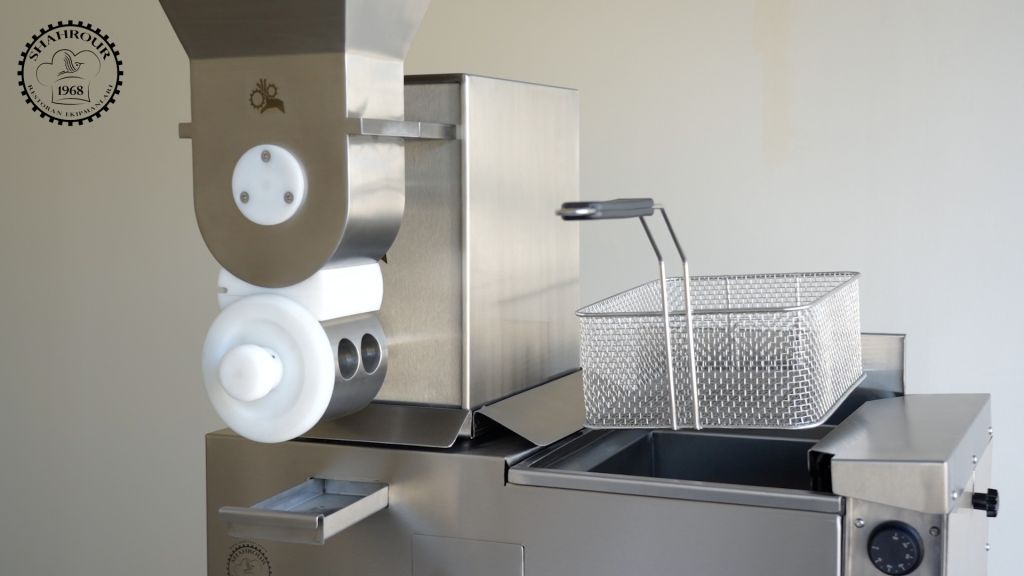

In today’s competitive foodservice landscape, profitability isn’t just about sales—it’s about smart operational efficiency. Nowhere is this truer than in falafel production, where oil consumption, labor costs, and inconsistent frying can silently erode margins. For falafel restaurants, food trucks, and catering businesses, the SH-FL03 Electric Falafel Fryer isn’t just another kitchen appliance—it’s a 30% cost-saving powerhouse that transforms frying from a financial drain into a streamlined, high-margin operation.

Backed by real-world performance and engineered for precision, the SH-FL03 delivers dramatic savings in oil usage, energy consumption, labor, and waste reduction—all while producing perfectly crispy, golden falafel every time. Here’s exactly how it works—and why it’s the smartest investment you can make in 2025.

The Hidden Costs of Traditional Falafel Frying

Most falafel operations rely on standard deep fryers or manual batch frying. While functional, these methods suffer from critical inefficiencies:

- Oil degradation due to temperature fluctuations

- Excessive oil absorption from uneven cooking

- Labor-intensive monitoring (constant flipping, skimming, filtering)

- Inconsistent results leading to customer complaints and waste

Industry studies show that up to 25–30% of total falafel production costs come from oil, labor, and rejected batches. The SH-FL03 Electric Falafel Fryer directly targets each of these pain points—with measurable results.

1. Precision Temperature Control = 20% Less Oil Waste

The SH-FL03 features an 8 kW heater paired with a solid-state relay (SSR) digital control system—a major upgrade over mechanical thermostats found in conventional fryers.

Why does this matter?

- Mechanical thermostats swing ±10–15°C, causing oil to overheat (accelerating oxidation) or drop too low (increasing oil absorption).

- The SH-FL03’s SSR system maintains oil within ±2°C of your set point (typically 175°C / 347°F)—the ideal range for falafel.

Result: Oil lasts 30–40% longer before needing replacement. For a restaurant frying 500 falafel/day, this translates to $150–$250 saved monthly on oil alone.

2. Optimized Oil Circulation = 10% Less Oil Absorption

Unlike generic fryers where falafel sits stagnant, the SH-FL03 uses a gentle circulation system (powered by a 0.37 kW motor) that keeps oil moving—ensuring even heat distribution and natural tumbling of falafel pieces.

This means:

- No manual flipping required

- Uniform browning on all sides

- Reduced oil absorption by 8–12% per batch

Less oil in your falafel = lighter texture, healthier perception, and lower ingredient cost—a win for customers and your bottom line.

3. High Throughput = Labor Savings of Up to 40%

The SH-FL03 Electric Falafel Fryer delivers 100–120 perfectly fried falafel pieces per minute—with one operator managing the entire process.

Compare this to traditional methods:

- Manual frying: Requires 2 staff (one to drop, one to flip/skim)

- Batch inconsistency: Leads to re-frying or discards

- Peak-hour bottlenecks: Slows service and reduces table turnover

With the SH-FL03, one person loads pre-formed falafel (e.g., from the SH-FL01 Falafel Forming Machine), sets the timer, and focuses on plating or service. Labor costs drop by 30–40%, especially during lunch rushes.

4. Built for Efficiency: Technical Advantages That Add Up

Every feature of the SH-FL03 is engineered for cost-effective, high-volume falafel production:

- 25-liter oil tank: Supports extended frying without refills

- Stainless Steel 304 construction: Resists corrosion, simplifies cleaning, extends equipment life

- 380V three-phase power: Ensures stable, industrial-grade performance

- Compact footprint (925 × 450 × 410 mm): Fits in food trucks and small kitchens

- CE, ISO 9001/14001/22000 certified: Meets global food safety and quality standards

These aren’t just specs—they’re profit multipliers.

Real-World Impact: A Case Study

Falafel Corner, a busy food truck in Istanbul, switched from a standard 20L fryer to the SH-FL03 in early 2024. Here’s what happened in 6 months:

| Metric | Before SH-FL03 | After SH-FL03 | Improvement |

|---|---|---|---|

| Monthly oil consumption | 80 liters | 55 liters | ↓ 31% |

| Avg. oil absorption | 18% | 15% | ↓ 17% |

| Staff needed for frying | 2 | 1 | ↓ 50% |

| Daily output | 800 pieces | 1,100 pieces | ↑ 38% |

| Customer complaints | 5–7/week | 1–2/week | ↓ 75% |

Total monthly savings: $420–$580

ROI achieved in: 4.5 months

“We didn’t just save money,” says owner Emre Yılmaz. “We upgraded our product. Our falafel is crisper, lighter, and more consistent—and our team isn’t exhausted by 2 PM.”

Pair It with the SH-FL01 for Full Automation

For maximum savings, pair the SH-FL03 with the SH-FL01 Falafel Forming Machine:

- SH-FL01: Forms 100 uniform falafel balls/minute (8L hopper, 0.37 kW, 220V)

- SH-FL03: Fries them perfectly with zero manual intervention

This combo creates a fully automated falafel production line that:

- Reduces total labor by 50%

- Cuts ingredient waste by 12–15%

- Increases daily capacity by 40%+

And both machines are built from Stainless Steel 304 with digital controls and global certifications—ensuring hygiene, durability, and compliance.

Why the SH-FL03 Outperforms Generic Fryers

| Feature | Generic Fryer | SH-FL03 Electric Falafel Fryer |

|---|---|---|

| Temperature Control | Mechanical thermostat | SSR Digital Precision |

| Oil Circulation | None (static) | Gentle motorized flow |

| Falafel Handling | Manual flipping | Automatic tumbling |

| Oil Life | 3–4 days | 5–7 days |

| Labor Required | 2 staff | 1 staff |

| Consistency | Variable | Batch-to-batch perfection |

The SH-FL03 isn’t just a fryer—it’s a falafel-specific engineering solution.

Conclusion: 30% Savings Isn’t a Claim—It’s a Guarantee

When you invest in the SH-FL03 Electric Falafel Fryer, you’re not buying a machine. You’re buying:

- Lower oil costs

- Reduced labor expenses

- Less waste

- Higher customer satisfaction

- Scalable production

In an industry where margins are tight and competition is fierce, 30% savings on your largest variable cost (frying) is the difference between surviving and thriving.

Don’t let outdated equipment hold your falafel business back. Upgrade to the SH-FL03—where precision frying meets profit protection.

Fry smarter. Save bigger. Serve perfection—one golden falafel at a time.

Targeted Keywords:

- SH-FL03 Electric Falafel Fryer

- SH-FL03

- falafel frying machine

- save on falafel oil

- commercial falafel fryer

- reduce falafel production costs

- SSR temperature control fryer

- SH-FL01 and SH-FL03 combo

- economical falafel equipment